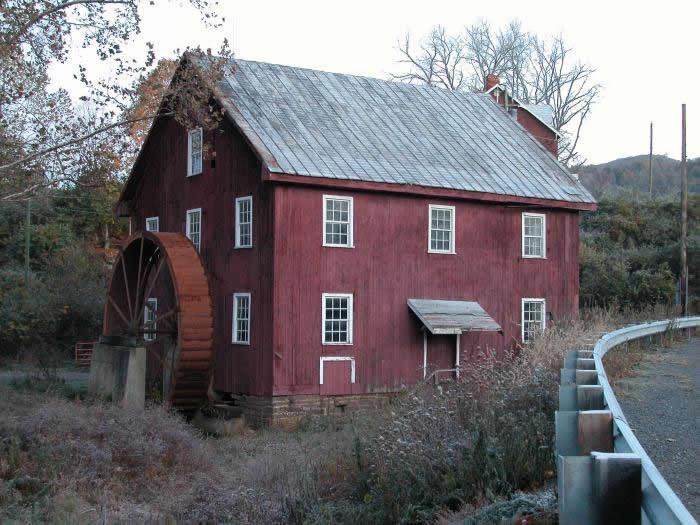

McNeel Mill / Mill Point Mill

Pocahontas Co. | West Virginia | USA

Watersource: Stamping Creek(Stomping Creek).

McNeel Mill / Mill Point Mill

Three miles north of Hillsboro, W. V. and 14 miles south of Marlinton, W. V. on US 219 just south ot the junction with Sh 39.

A 2.5 story frame mill on Stamping Creek, a tributary to the Greenbrier River, at a stop in the road called Mill Point. Entered into the National Register of Historic Places in 1985 and its period of significance indicated as 1850-1874, although it operated into 1942. Stamping Creek was originally called Stomping Creek because of the early practice that buffalo had of stomping holes in the mud along the creek bank. This must have been way before a mill was here and only the Indian's lore carried this down to the white men.

The owner of the mill, the large mill house and hewn log barn(over 200 years old), both made with hand-hewn black walnut logs, up until his death in 1980 was Richard L. McNeel. His grandfather, John McNeel, was a merchant in Edray near Marlinton about 1870-75. He sold out and moved down to the Mill Point-Hillsboro area where he bought the mill from a family named Matthews and built a store. The store was converted into a blacksmith shop in the late 1890's and a new store built. The blacksmith shop washed away in a flood in 1935 as did the dam for the mill, which was about 3/4 mile upstream on Stamping Creek to its spring fed origins. A millrace, of which half is still visible, brought water down to the mill to supply the original double turbines to operate the two stands of rollers and the two sets of buhrstone, one for corn meal and the other for buckwheat flour. The overshot wheel was added later, as the turbines required a faster flow to operate effiently.

*Update: The mill before the large water wheel was installed. A smaller, metal water turbine was used to power the mill.The original overshot water wheel was installed in 1921. The present wheel replaced it in the 1980s. Ted Hazen 06/02/2009*

A thank you from Renee Myers-12/09/2017. I am Richard "Dick" Myers' oldest grandchild, his passing when I was a senior in HS. I grew up min Indiana, but always loved the farm and Mill Point, appreciated our family's history, and spent as much time there as I could while growing up and as an adult. I happened onto your site and cannot put into words how it feels to go back in time through the photos and history you share. My grandfather, "Gramps", was a fine, respected man, who proudly and respectfully carried on the McNeel name. He died of emphysema way too soon. Thanks for sharing the photos and history of the McNeel Mill.

At the NcNeel Mill, farmers brought grain and corn to be ground and many stayed overnight. The stock was put up in the log barn, two stalls called "mill stables" and the farmers put up in the miller's house. Breakfast was provided, part of the service provided for those partonizing the mill. One reason the mill closed in 1942, was the impossibility of getting the linen cloth needed for the flour sifters, due to the war with Japan. The mill has some posters displayed advertising the 1895 Greenbrier Valley Fair. The mill is thought to be one of the oldest of its kind in the State of West Virginia. It is only about 2 miles north of the Hillsboro birthplace of Pearl S. Buck, born 1892, a reknown author of novels about China in the late 1800's-early 1900's. She later lived within 2 miles of the site manager's birthplace in SE Pennsylvania.

An outside covered stoop allowed barrels to rolled right onto a wagon bed from the mill. The mill still contains equipment to pack flour into barrels, which weighed 300 lbs. apiece. McNeel's grandfather, father and McNeel himself all operated the mill. Wheat entered the hoppers, then was transferred via buckets fastened to a pulley-driven belt to screens, the grain was cleaned, and elevated to the third floor. It then came down through the roller mills, then back to the third floor again, and through the sifter. The sifter separated the bran and the middlings. The middlings were a middle grade flour that still contained many hull pieces. Most of the final screenings were used in livestock feeds, while the flour was put through the roller mechanism until grade 1 or gbrade 2 flour was obtained.

The millstone jacks were used to lift the upper stone off the nether stone, so that both could be dressed by the millwright. The jacks also set the closeness of the upper stone to the lower stone. If too close, the flour would heat and burn, filling the whole mill with the odor. Fineness of the flour could be determined by rubbing a sample between the thumb and forefinger. Another feature many mills had was a sack hoist to enable the miller to use the power of the mill operation to pull sacks to higher floors of the mill. This was usually in the front of the mill, the rope running through a pulley in an overhang close to the roof, or an extension of the roof, and operated by the miller from any level. Pulling on the rope would tighten a belt running over an ever turning shaft. The rope lift would operate like a winch, winding the slack rope and hauling the sacks or barrel upward. Putting less pressure on the control rope would slow, stop, or reverse the movement of the objects being lifted.