Eve Mill / Fowler's Mill

Monroe Co. | Tennessee | USA

Watersource: Fork Creek.

Eve Mill / Fowler's Mill

From I-75, take exit 72/Loudon and go south on Sr 72 about 3 miles to Loudon Road/Steekee Road at a traffic light. Turn right/south on Loudon Road and go 5.9 miles to the mill on the right.

View Larger Map

The south or creek side of the mill from Steekee-Loudoun Road. This mill was built in 1875 on the site of the earlier Eve Mill. That is the name of the little village today.

The north side of the mill, which looks like a low barn from this vantagepoint. PS: 35' 38.60N, 84' 18.70W 856'/261 meters Chattanooga Quadrangle

The dam on Fork Creek right at the rear of the mill. Meal and whole wheat flour were produced on a Meadows 24" mill built in 1947 and power was supplied by a Samson turbine.

The dam & mill as viewed from the concrete bridge over Fork Creek. Mill owner in 2011 was Earl Alexander. Although the mill has not been operated since the 1990's, when Mrs. Alexander died, much of the mill equipment is present in the mill. The owner's daughter lives beside the mill.

A large pulley mountd on the shaft that drives the set of stones in the mill. The pulley means that it might also be drivable using a belt attached to an electric motor or to a farm tractor pulley. It may also mean that had a fixed pulley to drive an additional piece of machinery within the mill, using the same water-power, by connecting a belt to the pulley and to a pulley on the other mechanism.

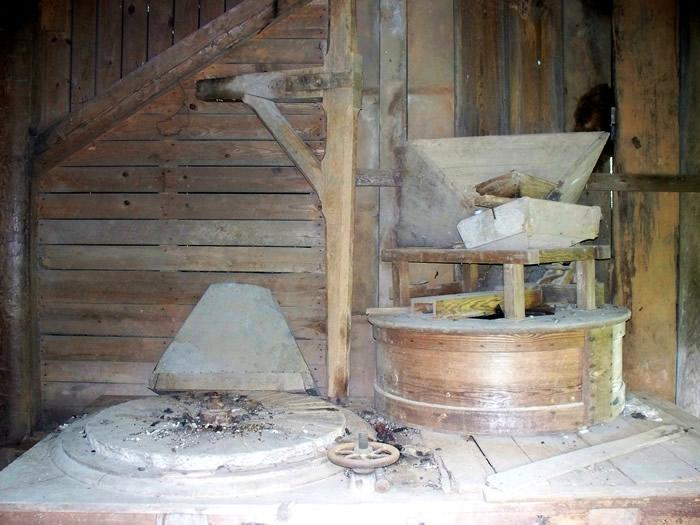

This stone set, showing the lower millstone is turned by the shaft in the photo above. Another stone would be placed on the steel prong protruding from the middle of the netherstone, and it is this upper stone that would turn on the lower stone. The space would be determined between the stones to provide the quality of flour desired. The stone crane is behind the stone set and the cover is to the right, with its hopper/feeder. No upper stone is visible.

The miller would have to keep the lands and grooves sharpened on the stone; as well as, determine when the stones were getting to warm by "keeping his nose to the grindstone"/smelling the resulting flour product for any sign of scorching or burnt smell.