Boggs Mill

Pendleton Co. | West Virginia | USA

Watersource: North Fork, South Branch of the Potomac River

Boggs Mill

Located off US 33/Sr 28 about 1.5 miles SW of the community of Seneca Rocks. Take the first left after the turnoff to right to Seneca Shadows Campground. The turn off to left is opposite a mobile home park on the hill on the right and about 2000’ north of the Mackville Mart, west side of highway. The turn splits immediately, keep left. Best to park on side of dirt trail and walk down to the mill, down and to the right, about an 8th mile.

The mill was built about 1830, and is a 3 1/2-story, rectangular, gable front building. It has clapboard siding and was constructed using mortise and tenon, braced frame construction. It sits on a stone foundation and has a standing-seam metal roof. The mill remained in operation until 1966, possibly converted to the roller process; it was damaged by a severe flood in 1985.Information taken from: United States Department of the Interior National Park Service-NATIONAL REGISTER OF HISTORIC PLACES form.

Most likely the mill was constructed by Jacob Carr, the original owner of the property. Carr was an immigrant who settled in the late eighteenth century in what was then Virginia. The mill was built sometime prior to 1820 as it is mentioned in a deed when Can sold the mill and surrounding property to John Boggs in 1820.

Seneca Rocks as viewed from the community of Seneca Rocks at the junction of US 33/Sr 28 with Sr 55.The mill is located about 250 yards west of the North Fork, South Branch of the Potomac River and was, at one time, connected to the river by a long mill race which led from the upstream dam to the mill. Most of the mill race has filled in over the years although an outline of it can still be seen. The dam foundation still remains. A dirt road connects the mill to US Route 33/State Route 28. The road, about ½ mile long, is in good condition and was used by the mill owners for farming the property around the mill until recent years.

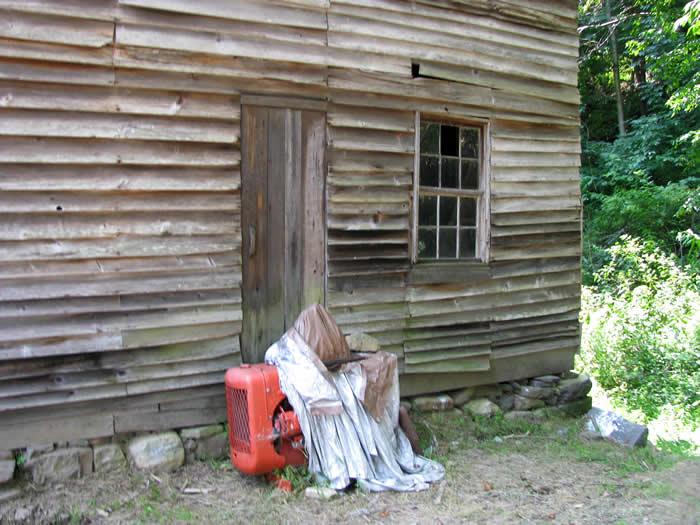

The Allis Chalmers engine may have powered the mill prior to it's closing in 1966.The mill was built in typical early eastern water mill construction and was originally two stories. The third story was added in the mid nineteenth century. While several of the openings have been boarded over, existing windows are six-over-six double-hung sash. The water wheel was damaged and removed in the 1985 flood. A shed roof along the south side of the building was also removed.

The mill was powered by water from the North Fork River. Upstream from the mill was a dam where water from the river was diverted to a mill race which ran to the west side of the mill. At the mill, the water was again dammed so that a stream of water could run through a pipe to the top of the mill wheel. The mill wheel was constructed of wood with a series of water buckets on the outer rim into which the water from the pipe would run. The weight of the water filling each bucket would force the wheel to turn. The system worked will as long as there was water in the river. In dry weather when the water dropped in the North Fork the mill would shut down if the water level was too low behind the dam.

The ground floor includes the mill stone and office. The second floor includes the fine sifting machinery. The gyrating screen dates to 1911. This machinery operated as follows: As a rotary movement is imparted to the shaft…, the weighted members…will be thrown out by centrifugal force…and thus produce the required gyratory motion, the speed at which the shaft rotates governing such gyratory movement imparted to the sieve. The grinding machinery, including three 1906 grinding mills/roller mills, are located on the third floor. The light-weight rafters on this floor, and the more modern flat top-plates for the upper wall, indicates that the top section of the building is of later construction. All the milling machinery inside the mill is in remarkably good condition with some of the leather drive belts still attached to the drive pulley wheels. The machinery has sustained very little rust and still shows oil stains on the bearings. With the correct cleaning and proper maintenance, this machinery could be put to use immediately. Fortunately, the flooring is intact and all machinery is firmly bolted to the floor boards.

The mill remained in the Boggs family for many years. It was eventually run by Frank Boggs, a descendant of John Boggs. Frank not only sold flour and feed, he also used the mill for grinding products for local farmers. One of Frank's ads read, "F.M. Boggs & Co.; Mouth of Seneca, W.Va.; White Rose Flour Makes Better Bread; A Full Line of Feed for Every Requirement." Grain was brought to the mill by the farmers to be ground for flour and feed (mixed grain used to feed cattle, hogs, and chickens). Most farmers brought their own grain in to be processed but many actually bought the finished flour or feed from Frank. For those who brought their grain to be ground into flour, he would charge a milling fee for grinding. For those who want to purchase flour or feed, Boggs charged by the pound. Local farmers brought their grain by wagon to the mill. The product was ground by forcing it between two large, rotating flat stones which have groves cut in them so as to allow the ground grain to move from the center of the stones to the outer rim of the mill stones. In the case of flour, this rough cut grain was then further ground and sifted so that the hulls were removed before being bleached into white flour. Whole wheat would retain all the ground grain and was not bleached. Grain which was to be used for animal feed required a shorter process and the finished product was not bleached or sifted. The rough cut grain was carried to the various levels by a system of cup conveyors which were operated by belt drives off the main mill wheel.

An office was maintained on the first floor of the mill where business was transacted. Also on the first floor was a flour room where flour was stored. By the 1960s farmers tended to buy more processed feed for animals than flour as that was by then readily available and inexpensive in stores. The mill was in operation until Frank Boggs sold the mill and property to Ward and Louise Bowers in 1966. GPS: 38° 49.17' N 79° 23.14' W ele 1,572 feet'/479 meters Onego QuadrangleSummary: For 136 years this mill operated continuously and has survived years of inclement weather, a Civil War battle fought nearby, and a severe flood in 1985. Boggs Mill stands as a testament to the builder's skill and to the hard work of the Boggs descendents who kept the mill working. Over the years, this mill has served the small community of Seneca Rocks as a grain mill, a retail store, and a community gathering place for residents. The property owners have undertaken an effort to stabilize the building, preserve it, and eventually operate the mill for educational purposes.